L&S Technology Blog

Technology Blog

While we've embraced digital transformation as a way to improve our productivity and quality, digital systems can only take you so far in a machine shop. At the end of the day, we also need to focus on physical systems that help us become more efficient. For instance, how do we make sure we always have the right cutting tools and manufacturing aids in the right place at the right time?

At L&S, we’re always looking for new ways to be more productive. In that spirit, we’ve recently added a Haas pallet pool to one of our UMC-500 five-axis mills. Perfect for high-volume production runs, as well as high-mix, low-volume machining, this new system lets us get more products out the door quickly, making us faster and more efficient for our customers.

While a part’s design may meet all the right functional requirements, that doesn’t mean the design is suited for cost-effective CNC machining. In fact, some part features may be difficult or even impossible to machine as designed, which drives cost, quality and yield problems

When it comes to Design for Manufacturability (DFM), it’s clear that overspecifying certain part features — such as dimensional tolerances, grooves, holes and radii — will drive up your production time and costs. But surface finish can be a different story.

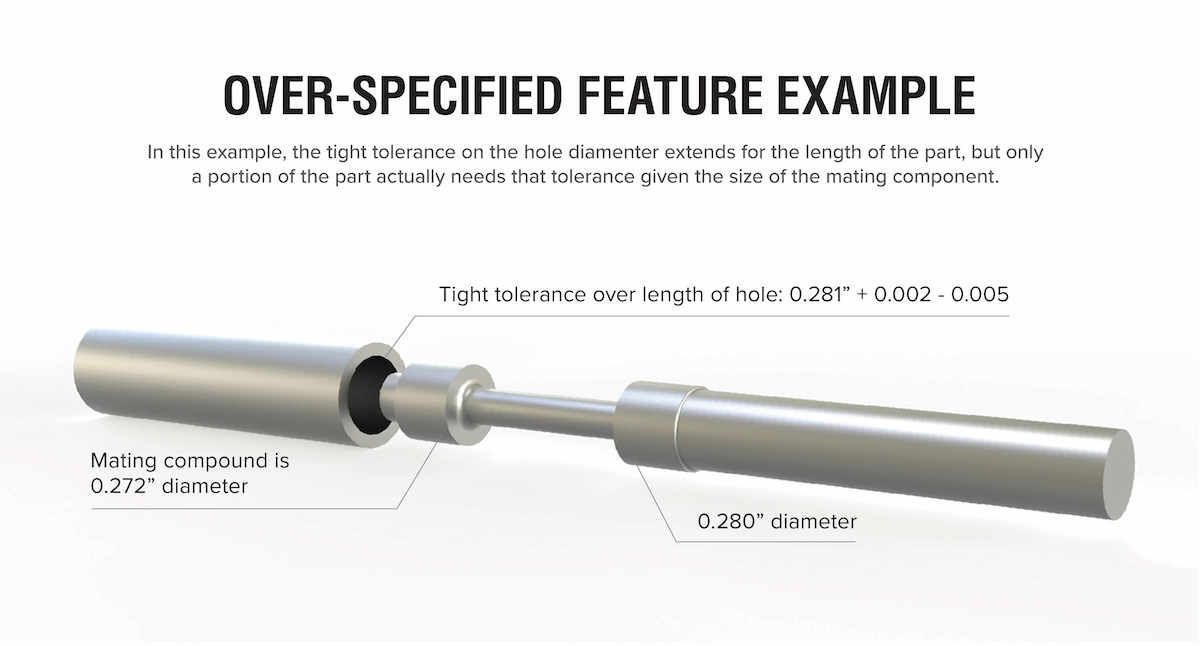

In our last blog post, we explored how overly tight dimensional tolerances on CNC machined parts can drive up production time, lead to more costly machining processes and reduce yields—making it a good idea to ask yourself if a part really needs the tightest of tolerances from a functional standpoint.

In our last blog post, we introduced six drivers of CNC machining time and cost. Kicking off this series, we turn our attention to dimensional tolerances. When overly tight, tolerances can easily drive up production time, lead you into more costly machining territory and reduce your yields.

While a part’s design may meet all the right functional requirements, that doesn’t mean the design is suited for cost-effective CNC machining. In fact, some part features may be difficult or even impossible to machine as designed, which drives cost, quality and yield problems.

At L&S, we've long been dedicated to working with local organizations to teach high school and college students about manufacturing as a way to stimulate their interest—and give them a glimpse of some great career opportunities. Before lockdown, we hosted two projects where students visited our Latrobe facility, watched our machine tools in action and learned about basic manufacturing processes in an interactive, hands-on way.

Just about every manufacturing business has a 3D printer nowadays. We’re one of them, and our 3D printer has improved our ability to make, inspect and handle parts for the nuclear, aerospace and medical industries. Here’s how we use it:

L&S is excited to work with Astrobotic Technology—a cutting-edge space robotics company based in Pittsburgh, Pennsylvania. Making the Moon more accessible to universities, non-profits, companies and individuals, Astrobotic provides end-to-end payload delivery to lunar orbit and the lunar surface.

Our facilities have been undergoing a transformation, and the biggest change has been a move to replace all of our 3-axis machines with new Haas 5-axis CNC machines. While we still have a handful of 3-axis machines for very simple jobs, the bulk of our production milling jobs now go on 5-axis machines. Here’s why:

We’re proud to announce that Lauren Morlacci, our Continuous Improvement Manager, was recently named one of the National Tooling and Machining Association (NTMA)’s 30 Under 30 honorees. She, along with 29 of her peers, will be recognized at the upcoming NTMA Fall Conference for her work in manufacturing.

An update on data-driven CNC machining at L&S Machine Company

Check out our new video to learn more about our full range of capabilities including CNC machining, 5-axis machining, welding, water jet cutting and quality systems. Only takes a minute.

If you’re involved in any type of manufacturing, you’ve probably given some thought to what the factory of the future will look like. How automated will it be? Will the machines have more advanced capabilities? And what human skills will be needed to run those machines?